A look inside Slate’s Michigan design studio and prototype facility

Slate expects to deliver a roughly $25,000 electric truck next year. We checked out some of its facilities to see how it’s planning to do it.

We took a tour inside Slate Auto’s Michigan headquarters, design studio, and prototype facility — where the company is designing its mid-$20,000 electric truck before it begins production at the end of next year. We spoke with the company’s CEO, Chris Barman, about how it’s trying to keep its promises of a low-cost EV while others have failed. We also snooped around to see what the startup is like inside.

The headquarters is mostly just an office — not much to look at. One of the few concessions to decor is that they plastered the company’s principles around the office.

A big one: “Fast, frugal and scrappy.”

At the nearby design studio, employees have been working on everything from the seats to the accessories. Inside, there are shelves showcasing their design inspiration, including Herschel backpacks, flasks, and outdoor gear:

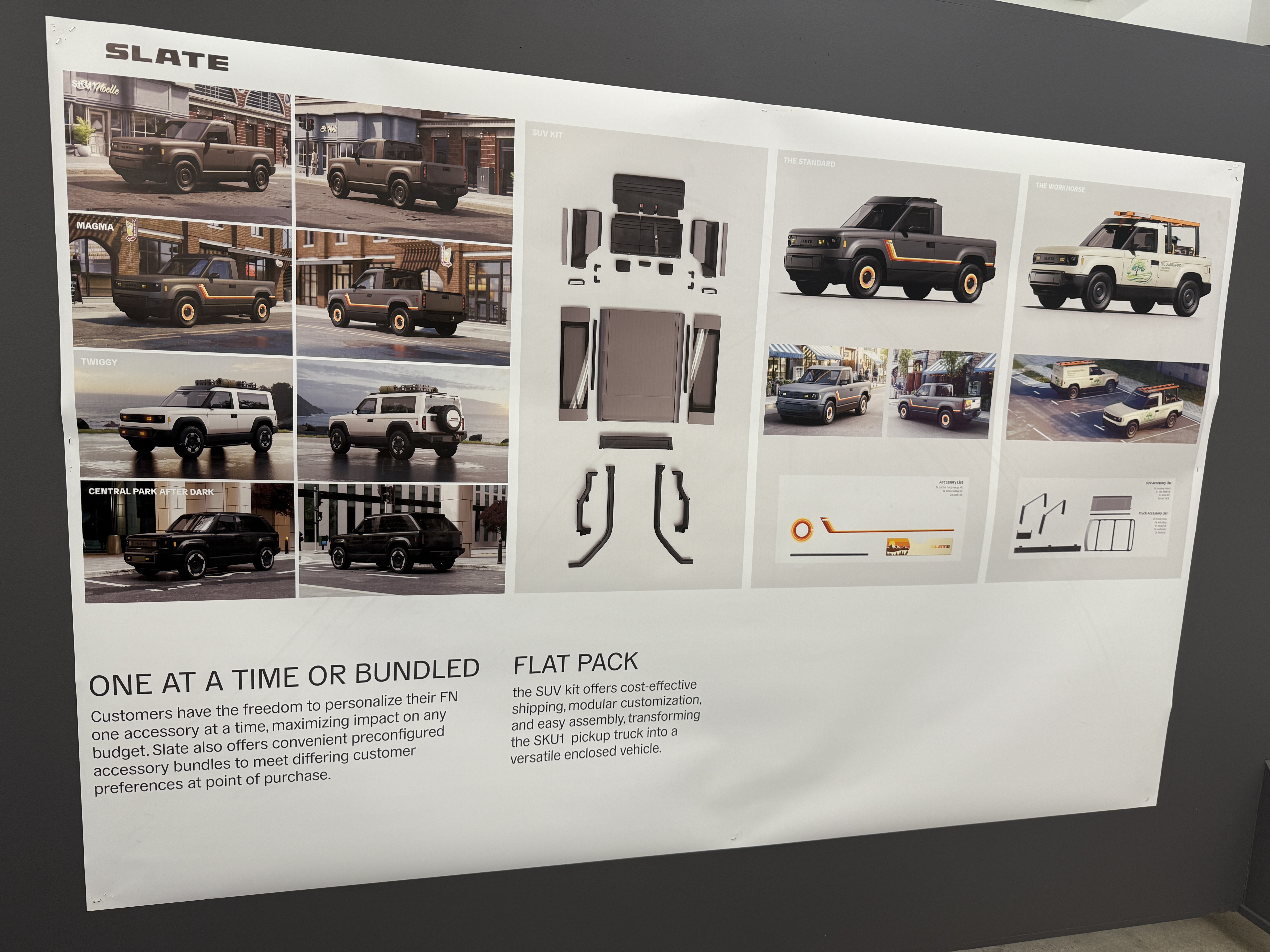

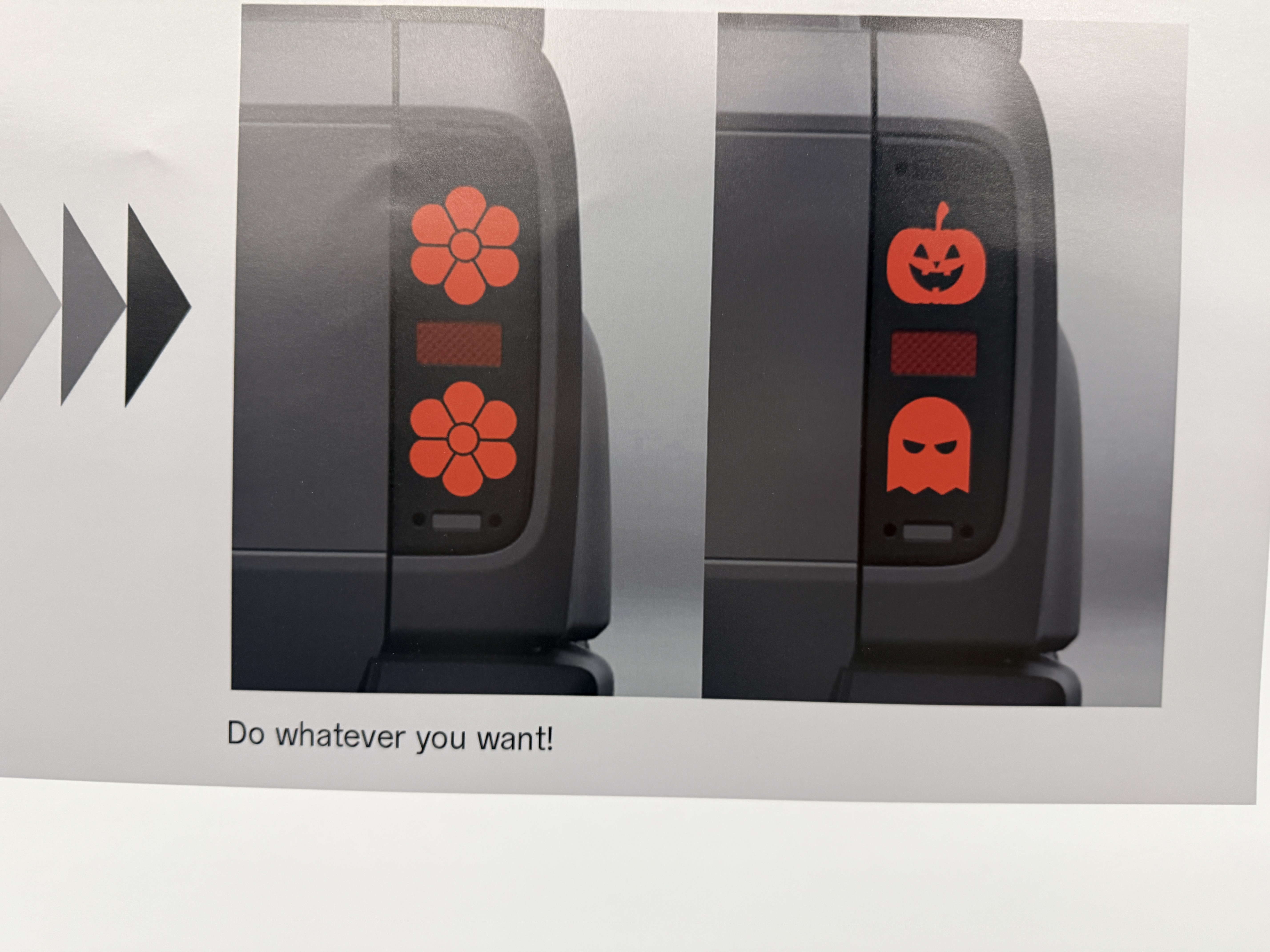

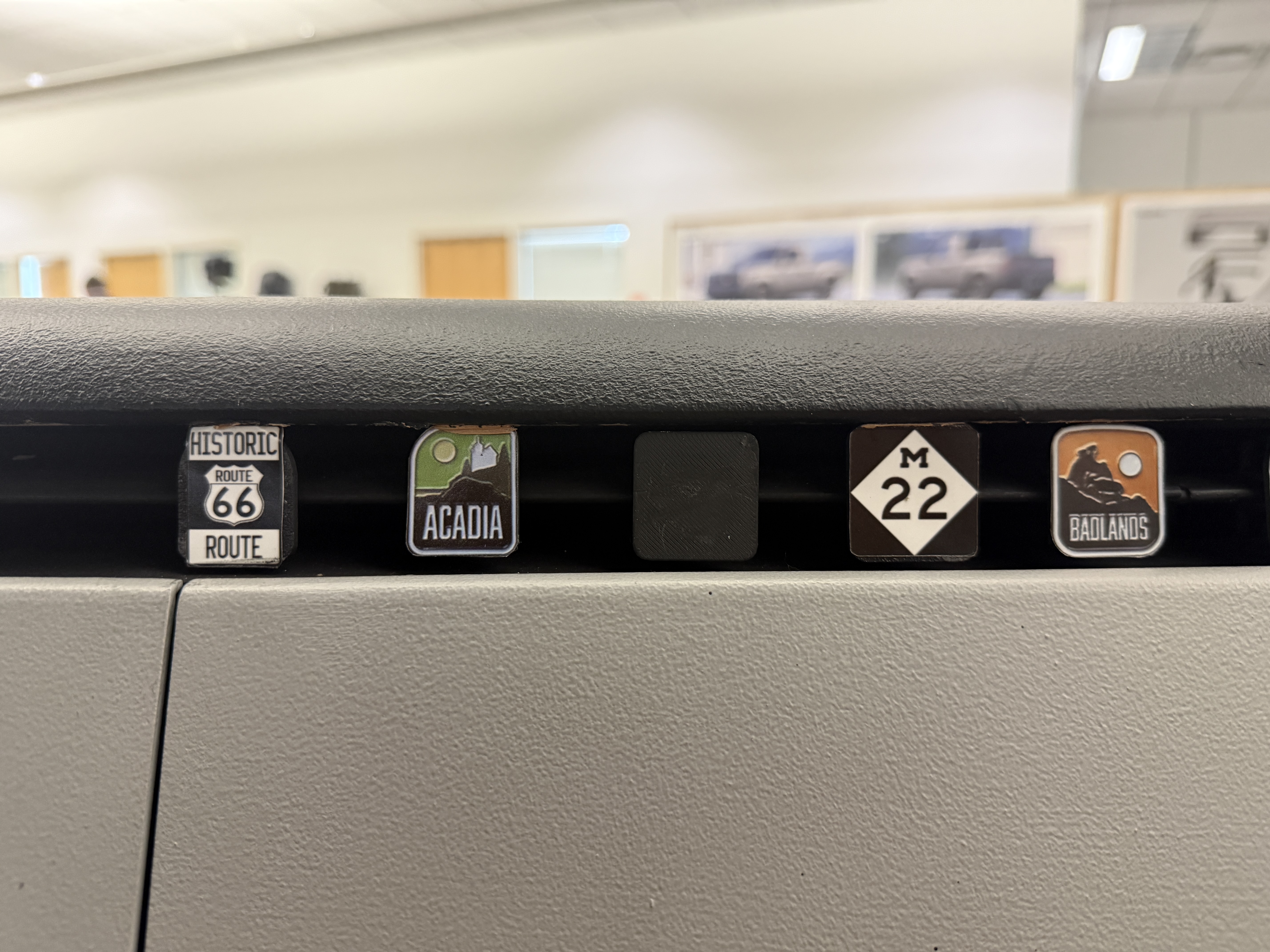

The inspiration above took them to a place without power windows or infotainment systems — but that’s also highly customizable. People can change the color of their trucks with DIY wraps, can alter its look with custom light covers, and can even buy parts that make the truck into a five-seat SUV.

The space houses a foam and clay seating buck, a full-scale physical model to simulate the car’s interior so the designers can get a sense of how different materials and accessories will look inside the truck. It’s pictured here with Hello Kitty luggage in the “frunk.” The real frunk will also have drainage for a cooler and cup holders so you can tailgate from the front.

The company’s beta prototype facility is about 20 minutes away, in a giant warehouse that formerly served as storage space for GM.

The facility also houses one of Slate’s alpha prototypes, which was really just a chopped up an retrofitted Mahindra Roxor:

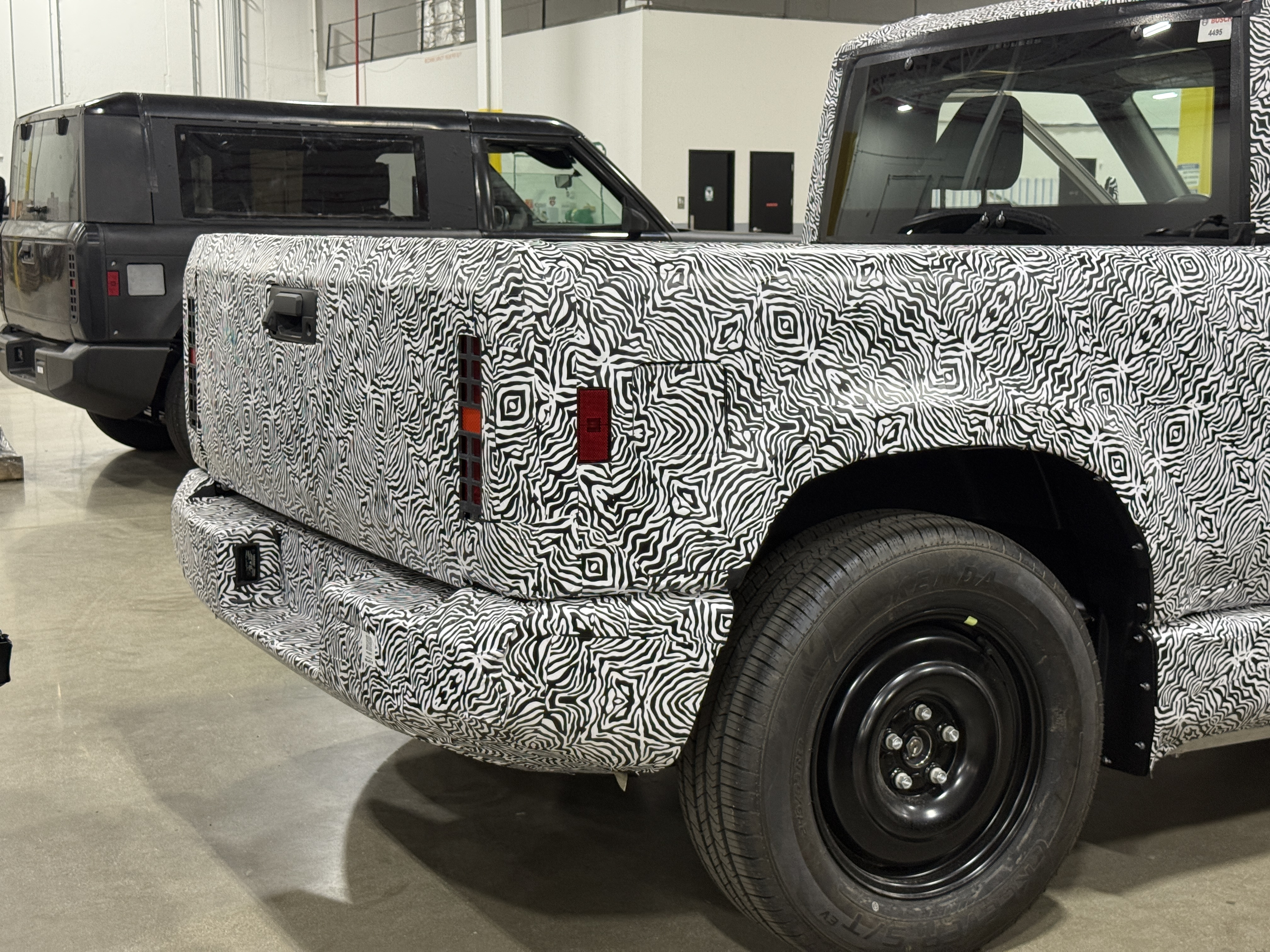

It was also filled with dozens of newer hand-built beta prototypes in various stages of construction before they’re shipped off for crash tests as well as promotional tours around the country.

You can watch it go from a pile of materials to a real truck. Slate’s CEO told me that while most cars have more than 2,500 parts, Slate has about 600 and thus can get away with a smaller facility than other carmakers.

.JPG)

Here’s what they look like when they’re finished:

They also actually drive. I know because they were able to prove that they work, as these videos show: